Producent

Mitsubishi Forklift Europe

Hefbrugweg 77 | NL-1332 AM Almere | Holandia | www.mitforklift.com

Historia / Informacje o firmie

Keeping thousands of companies at their most productive, the name Mitsubishi Forklift Trucks has become synonymous with quality, reliability, and value for money.

Our distinctive green trucks can be seen on work sites and in warehouses all around the world - with Mitsubishi forklifts, reach trucks, order pickers, pallet trucks and more all serving the backbone for some of the busiest and demanding operations around.

Innovative design, cutting-edge technology and uncompromising quality are standards that define everything we do.

Our award-winning product development team are world leaders in achieving the ultimate in driveability. At the same time, they define the green standards for fuel economy and low emissions.

Durable materials, low-wear systems and built-in protection all extend the truck's working life and extend service intervals. Meanwhile, RapidAccess features encourage your staff to carry out routine checks by making the process quick and easy - ensuring proper maintenance and so cutting your running costs.

With a range that includes over 150 different models, each available with a myriad of options, we can offer precisely the right truck for your exact needs.

Market-leading customer care is an essential part of the unique Mitsubishi package. Every dealer has been hand-picked for its facilities, knowledge, and commitment to our customers. And we are all backed by the huge resources of the global Mitsubishi organisation.

Wherever you are working - on a single site or across the country - we bring you the local knowledge and expertise to ensure the best possible solution for your business.

Obszary sprzedaży

The Netherlands; Deutschland; France; Great Britain; Ireland; Italy; Spain; Portugal; Russian; Sweden; Denmark; Norway and the Middle East Region

| Nazwa | Kontakt | Państwo | |

|---|---|---|---|

| Mitsubishi Gabelstapler Deutschland | +49 208 6567-0 | Niemcy | |

| Mitsubishi Forklift Trucks España | Hiszpania |

| Nazwa | Kod poczt. | Miasto | Państwo |

|---|---|---|---|

| ULMA | 20560 | Oñati - Gipuzkoa | Hiszpania |

| RIPROMAN, S.L. | 50298 | PINSEQUE (ZARAGOZA) | Hiszpania |

| WYLZE LOGISTIK SRL | 100514 | Ploiesti | Rumunia |

| KUHN Rakodogep Kft. | 1239 | Budapest | Węgry |

| SEEVIL d.o.o. | 1260 | Ljubljana-Polje | Słowenia |

| Quick Rentals B.V. | 1332 | 1332 AV Almere | Holandia |

| Logisnext Belgium BV | 1840 | Londerzeel | Belgia |

| NEUWERTH Logistics SA | 1957 | Ardon | Szwajcaria |

| PEGAMO S.A. | 20180 | Oiartzun, Gipuzkoa | Hiszpania |

| De Ronde NV | 2060 | Antwerpen | Belgia |

| LOUSA - voziky s.r.o. | 257 22 | Ctyrkoly | Czechy |

| Logisnext Mitsubishi Danmark A/S | 2670 | Greve | Dania |

| Alcamar S. A. | 28864 | Ajalvir | Hiszpania |

| Degrosolutions Srl | 36071 | Arzignano (VI) | Włochy |

| KUHN Polska Sp. z o.o. | 41-200 | Sosnowiec | Polska |

| Europieces | 4410 | Soleuvre | Luksemburg |

| Feyter Forklift Services b.v. | 4538 AM | Terneuzen | Holandia |

| Logisnext Germany GmbH | 46149 | Oberhausen | Niemcy |

| Ontieleva S.L.U | 46870 | Ontinyent | Hiszpania |

| KUHN Ladetechnik GmbH | 4840 | Vöcklabruck | Austria |

| Lenormant Manutention sas | 60000 | Beauvais | Francja |

| Lima Intern Transport | 6014 CG | Ittervoort | Holandia |

| Manustock | 64100 | Bayonne | Francja |

| Samie S.A. | 67100 | Strasbourg | Francja |

| GP Servis Morava s.r.o. | 70200 | Ostrava-Přívoz | Czechy |

| Mulder Heftruckservice B.V. | 7071 EC | Ulft | Holandia |

| Afrelec Industrie - Société R.P.A | 71850 | Charmay les Macon | Francja |

| Logisnext Netherlands B.V. | 7547 TB | Enschede | Holandia |

| Kompactor B.V. | 7602 PE | Almelo | Holandia |

| FORKLIFT OÜ | 85008 | Pärnu | Estonia |

| BETA - CARS s. r. o. | 90201 | Pezinok | Słowacja |

| Logisnext Finland Oy | 01380 | Vantaa | Finlandia |

| Logisnext Sweden AB | 02159 | Mölnlycke | Szwecja |

| Logisnext Norway AS | 1481 | Hagan | Norwegia |

| Stenborgs Truckar AB | 176 02 | Järfälla | Szwecja |

| Mitsubishi Forklift Trucks España | 28027 | Madrid | Hiszpania |

| LS Manutention | 57855 | Saint-Privat-la-Montagne | Francja |

| Gilles Morel SARL | 63370 | LEMPDES | Francja |

| Aurama Manutention | 69740 | GENAS – FRANCE | Francja |

| CENTRE EUROPE MANUTENTION | 87220 | LIMOGES | Francja |

| Ile de France Manutention (IFM) | 95192 | Goussainville Cedex | Francja |

| Logisnext France | 95310 | Saint Ouen | Francja |

| Henley Forklift Group Ltd | D10 | Dublin 10 | Irlandia |

| Vivier Manutention | FR-62223 | St. Catherine Lez Arras | Francja |

| Logisnext UK Limited | OX9 3RR | Thame | Wielka Brytania |

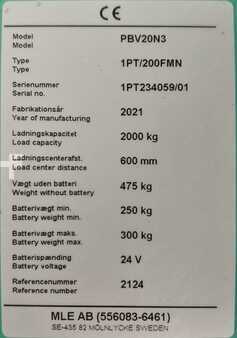

2019 Mitsubishi PBV20N2

2023 Mitsubishi FB25ACN - Neugerät! - 1 Std. - HH 5.060 mm

2023 Mitsubishi FB25ACN - Neugerät! - 1 Std. - HH 5.060 mm

- 4 Wege Fingertipp Kontrolle - Bereifung nicht Kreidend - Deluxe Kabine - Luxus Sitz - Seitenschieber

(Automatyczne tłumaczenie):

Gabel Długość: 115 cm Dodatkowe urządzenia: - 4 sposoby sterowania końcówką palców - Opony nie kredowe - kabina luksusowa - luksusowe siedzenie - Slajd boczny, ładowarka bez przewodów UVV NOWOŚĆ! ...

Gabellänge: 115 cm Zusatzgeräte: - 4 Wege Fingertipp Kontrolle - Bereifung nicht Kreidend - Deluxe Kabine - Luxus Sitz - Seitenschieber, Akku-Ladegerät UVV neu! Ihr Gabelstapler und Lagertechnik Spezialist mit ...

(Automatyczne tłumaczenie):

Gabel Długość: 115 cm Dodatkowe urządzenia: - 4 sposoby sterowania końcówką palców - Opony nie kredowe - kabina luksusowa - luksusowe siedzenie - Slajd boczny, ładowarka bez przewodów UVV NOWOŚĆ! ...

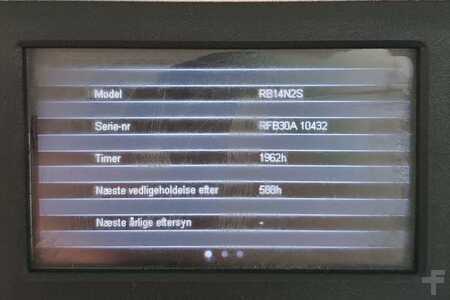

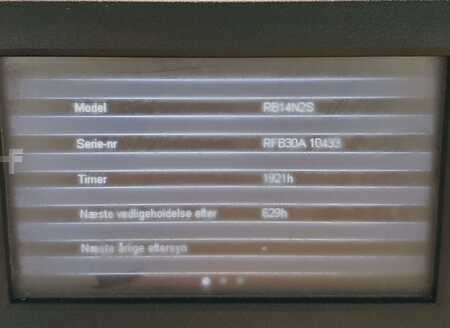

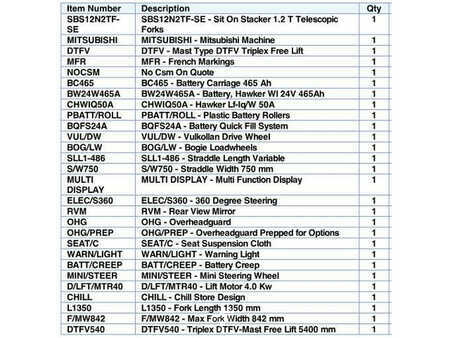

2024 Mitsubishi SBS12N2TF

2024 Mitsubishi SBS12N2TF

Verwendung: Interne Logistik; Akku: 465Ah, 24V, Batteriemarke Hawker; MIT-0028; Produktionsland: FI; Wenden Sie sich an Robert Kando (+31 882 053 055, +31 6 51 30 47 53, robert.kando@logisnext.eu), um weitere ...

(Automatyczne tłumaczenie):

Użyj: logistyka wewnętrzna; Bateria: 465ah, 24 V, Hawker marki baterii; MIT-0028; Kraina produkcji: FI; Skontaktuj się z Robertem Kando (+31 882 053 055, +31 6 51 30 47 53, Robert.kando@logisnext.eu), ...

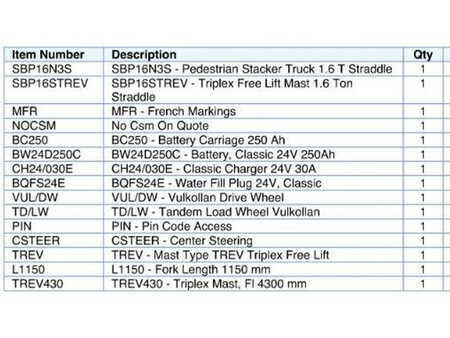

2024 Mitsubishi SBP16N3S

2024 Mitsubishi SBP16N3S

Verwendungszweck: Interne Logistik; Akku: 250 Ah, 24 V; Referenznummer: MIT-0025; Produktionsland: FI; Wenden Sie sich an Robert Kando (+31 882 053 055, +31 6 51 30 47 53, robert.kando@logisnext.eu), um ...

(Automatyczne tłumaczenie):

Korzystanie z celów: logistyka wewnętrzna; Bateria: 250 AH, 24 V; Numer odniesienia: MIT-0025; Kraina produkcji: FI; Skontaktuj się z Robertem Kando (+31 882 053 055, +31 6 51 30 47 ...

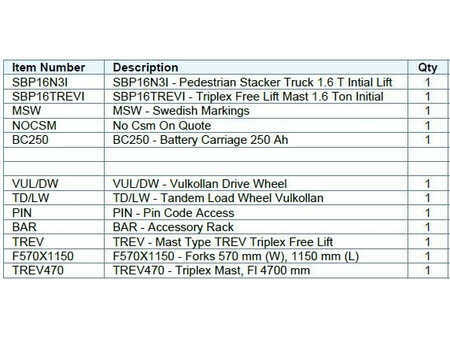

2024 Mitsubishi SBP16N3I

2024 Mitsubishi SBP16N3I

Verwendungszweck: Interne Logistik; Akku: 250 Ah, 24 V; Referenznummer: MIT=0033; Wenden Sie sich an Robert Kando (+31 882 053 055, +31 6 51 30 47 53, robert.kando@logisnext.eu), um weitere Informationen ...

(Automatyczne tłumaczenie):

Korzystanie z celów: logistyka wewnętrzna; Bateria: 250 AH, 24 V; Numer odniesienia: z u003d 0033; Skontaktuj się z Robertem Kando (+31 882 053 055, +31 6 51 30 47 53, ...

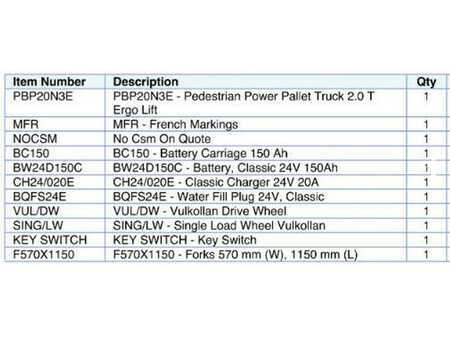

2024 Mitsubishi PBP20N3E

2024 Mitsubishi PBP20N3E

Verwendungszweck: Interne Logistik; Akku: 150 Ah, 24 V; Referenznummer: MIT-0027; Produktionsland: FI; Wenden Sie sich an Robert Kando (+31 882 053 055, +31 6 51 30 47 53, robert.kando@logisnext.eu), um ...

(Automatyczne tłumaczenie):

Korzystanie z celów: logistyka wewnętrzna; Bateria: 150 AH, 24 V; Numer odniesienia: MIT-0027; Kraina produkcji: FI; Skontaktuj się z Robertem Kando (+31 882 053 055, +31 6 51 30 47 ...

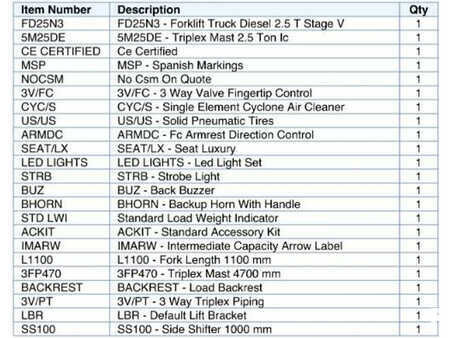

2025 Mitsubishi FD25N3

2025 Mitsubishi FD25N3

Verwendungszweck: Interne Logistik; Referenznummer: MIT-0032; Produktionsland: ES; Wenden Sie sich an Robert Kando (+31 882 053 055, +31 6 51 30 47 53, robert.kando@logisnext.eu), um weitere Informationen zu erhalten.

(Automatyczne tłumaczenie):

Korzystanie z celów: logistyka wewnętrzna; Numer odniesienia: MIT-0032; Kraina produkcji: ES; Skontaktuj się z Robertem Kando (+31 882 053 055, +31 6 51 30 47 53, Robert.kando@logisnext.eu), aby uzyskać dalsze ...

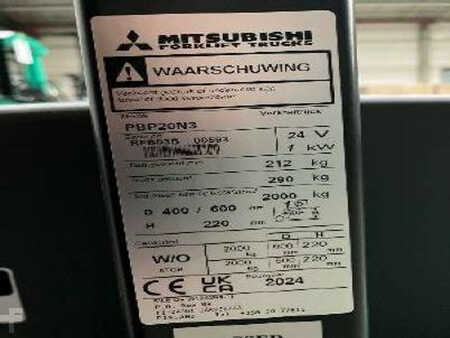

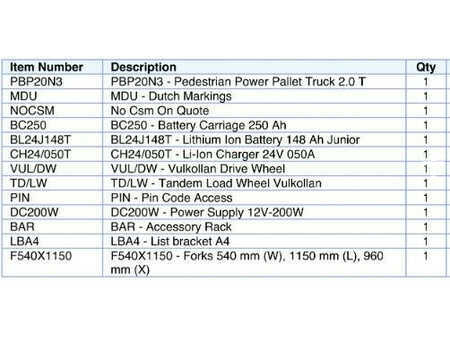

2024 Mitsubishi PBP20N3

2024 Mitsubishi PBP20N3

Verwendung: Interne Logistik; Akku: 150Ah, 24V, Batteriemarke Li-ion Battery; MIT-0030; Produktionsland: FI; Wenden Sie sich an Robert Kando (+31 882 053 055, +31 6 51 30 47 53, robert.kando@logisnext.eu), um ...

(Automatyczne tłumaczenie):

Użyj: logistyka wewnętrzna; Bateria: 150ah, 24 V, bateria lit-jon marki baterii; MIT-0030; Kraina produkcji: FI; Skontaktuj się z Robertem Kando (+31 882 053 055, +31 6 51 30 47 53, ...

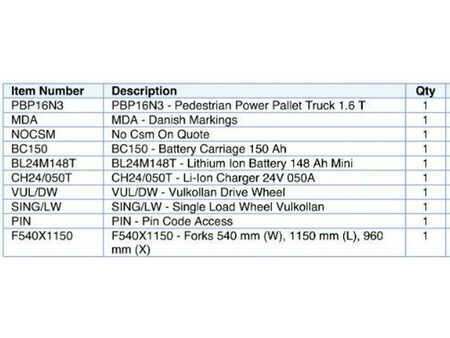

2024 Mitsubishi PBP16N3

2024 Mitsubishi PBP16N3

Verwendung: Interne Logistik; Akku: 150Ah, 24V, Batteriemarke Li-ion Charger; MIT-0029; Produktionsland: FI; Wenden Sie sich an Robert Kando (+31 882 053 055, +31 6 51 30 47 53, robert.kando@logisnext.eu), um ...

(Automatyczne tłumaczenie):

Użyj: logistyka wewnętrzna; Bateria: 150ah, 24 V, ładowarka lit-jon marki baterii; MIT-0029; Kraina produkcji: FI; Skontaktuj się z Robertem Kando (+31 882 053 055, +31 6 51 30 47 53, ...